Groundbreaking innovations shine at PIT Symposium

Innovation drives Exxaro’s success and sustainability. Each year, top developed talent generates groundbreaking ideas for operational challenges, with the top eight presenting at the Professionals-in-Training (PIT) Symposium. This event, a highlight on Exxaro’s development agenda, challenges young professionals to offer innovative solutions to Business Unit challenges. Projects involve collaboration, research, and benchmarking, with eight finalists chosen from 36 participants to showcase how their ideas contribute to Exxaro’s mission of “Powering Better Lives in Africa and Beyond”. Congratulations to the winners and well done to all who contributed to Exxaro’s ongoing success and sustainability.

Individual 2nd Place

Malebo Miyambu

Chemical Engineering:

Grootegeluk

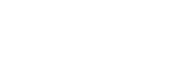

Individual winner

Koena Monene

Mining Engineering:

Matla

Individual 3rd Place

Clement Semenya

Metallurgical Engineering:

Grootegeluk

Individual 3rd Place

Marubini Ndou

Electrical Engineering:

Matla

Project:

Magnetite optimisation at the drain and rinse screens

Project:

Mining the future tody

Project:

GG2 thickeners optimisation through D@E project

Project:

Regenerative braking system for an underground decline conveyor belt

Magnetite consumption is a critical plant KPI, and its scarcity demands enhanced management. Current sprayers face challenges, resulting in reduced magnetite recovery. The implementation of power nozzles at GG1 has significantly improved recovery, especially at module 26, suggesting their effectiveness in addressing high magnetite consumption. Thorough evaluations it indicates a potential annual value of R59 million from this project.

Over the years, Life of Mine projects (LOM) projects have been crucial to extending Malta’s mining beyond initial plans. The Mine 1 first coal project holds critical significance as it aims to enhance both coal volumes and qualities that Matla Coal supplies to Matla Power for energy generation, thereby improving the overall Rand per tonne. Its success aligns with Exxaro’s strategy to maintain a robust coal portfolio and ensure ongoing value delivery from the coal business.

Thickeners play a vital role in separating slurry for filter plant feed and clear water re-use, reducing freshwater dependency. The GG2 thickeners face challenges causing production downtimes and disruptions. The project primarily targeted mitigating thickener high torque impact, promoting environmental sustainability through digitisation and automation. By preventing fines pumping to slime dams, mitigating rake failure, and managing downstream processes, the project also enhanced operational efficiency, reduced downtime, and optimised resource utilisation for a more sustainable and efficient operation.

The mining industry faces sustainable development challenges, with energy efficiency being crucial. Effective braking control for a decline conveyor is essential to prevent excessive belt movement and unnecessary wear. Downhill conveyors, including the interseam belt, require a braking system for smooth starting and stopping. The project explored various approaches for efficient braking. In the end, a braking mechanism was chosen, and a speed control algorithm developed in line with the user requirements and specifications.

<

>